PROJECT OVERVIEW.

The 974m long double track Marrangaroo Rail Tunnel is situated on the Great Western Railway Line between Lithgow and Bathurst, NSW. The surrounding geology is sandstone and siltstone up to 100MPa in strength. There is a considerable flow of underground water which has led to drainage problems

Beneath the Rail

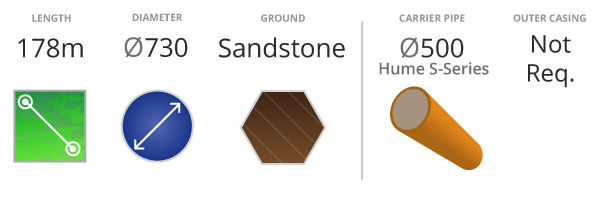

After the award of the tender, Pezzimenti worked with the ARTC to redesign the drainage line to minimise risk to the rail line. The new design focused on keeping all microtunnelling out of embankment fill and crossing the rail line at a depth of 6m in stable sandstone. A portion of the drainage line was to be laid in open cut due to fill ground and shallow depths. The new design required a microtunnel 178m long at 1% grade run from the edge of the rail tracks at the end of the cutting and breakthrough in the proposed drainage pit at the end of the tunnel portal.

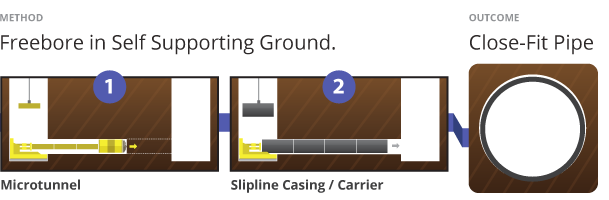

Flexibility and Freeboring

The flexibility of the freeboring technique, which enables the head to be withdrawn back through the self-supporting ground, made the design feasible as it was not possible to remove the head at the tunnel portal. Very high ground water inflows were experienced during construction. The microtunnelling was completed and the 500mm diameter S-Series jacking pipes from Humes were inserted. Excavation of the pits, laying of the open cut sections and construction of the concrete drainage pits was completed by Roberts Civil.

6m deep launch shaft. The freebore was required to exit in a drainage pit on the left hand side of the tunnel portal.

Shaft setup adjacent to the tracks.

Site setup. Vacuum power unit and fresh water tank were setup away from the launch shaft.

MICROTUNNEL 1.

Close Fit Pipe by Freebore Method

Length. 45m

Diameter. 700

Ground. Sandstone Shale

Casing Pipe. None

Carrier Pipe. 500 S-Series

MICROTUNNEL 2.

Close Fit Pipe by Freebore Method

Length. 78m

Diameter. 700

Ground. Sandstone / Shale

Casing Pipe. None

Carrier Pipe. 500 S-Series

MICROTUNNEL 3.

Close Fit Pipe by Freebore Method

Length. 178m

Diameter. 700

Ground. Sandstone / Shale

Casing Pipe. None

Carrier Pipe. 500 S-Series