PROJECT OVERVIEW.

Microtunnelling Ground Conditions

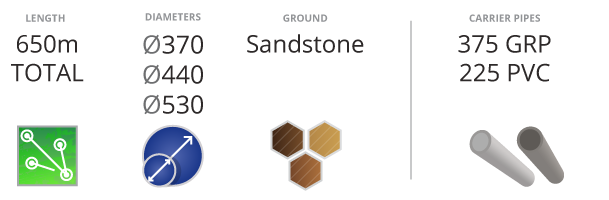

The sewer diversion required the microtunnelling of 650m in sandstone and diverted sewage flow from the main carrier flowing to the headland SPS to existing SPS 1129 on Hickson Road.

The Project developer was Lend Lease, the civil contractor was Baulderstone (now a subsidiary of Lend Lease).

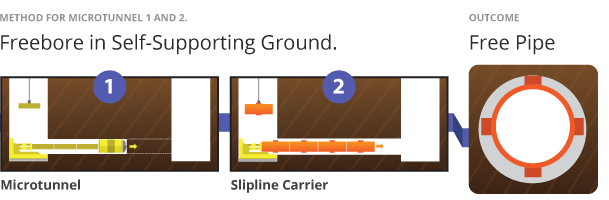

The geotechnical investigation revealed the microtunnel was to be fully located in stable sandstone. The presence of stable, self-supporting sandstone allowed for the microtunnelling method of freeboring and the elimination of the need for any outer encasing pipes for ground support. This design saved considerable cost and time.

Design amended eliminates disruption.

The presence of the sandstone also allowed the design to be optimised to drill under Dalgety Rd rather than be located in Towns Place. The designers were initially hesitant of locating a microtunnel under a hill where the depths to invert were up to 15m.

Their concern was that should the microtunnelling head become jammed during drilling, there was no way it could be retrieved by excavation from the surface. The Towns Pl design would have caused considerable disruption to the newly landscaped area and made pipe laying extremely costly in fill ground located close to the Sydney Harbour and subject to high seawater inflow rates.

After submissions to the designer and a log of previous projects successfully completed by Pezzimenti Tunnelbore, the design was amended to the Dalgety Rd route, eliminating disruption to Towns Place and saving considerable cost.

Setup under Windmill street overpass

View of the Hickson Road shaft from High Street.

Crane truck and semi trailer vacuum truck positioned to allow freeflow of traffic along Hickson RD

Microtunnelling under Hickson Road directly into the wet well of SPS1129

The Luna Park Fault Line

The geotechnical investigations also revealed the presence of the Luna Park fault line. The fault line ran in the same alignment as the microtunnel under Dalgety Rd. The information available showed there was a vertical displacement across the fault of some 600mm.

There was the real possibility of very high sea water inflow if the fault linked the microtunnel alignment to the harbour. As it turned out, the fault had no adverse effects on the microtunnelling and the 137m bore.

Contaminated ground at the SPS

The presence of contaminated ground was well known and researched for the project. The contaminated ground was known to be present in the upper layers of soil around the existing SPS in Hickson Rd. Excavation of this contaminated ground was not allowed. Investigations showed the contaminated ground did not extend to the depths of the microtunnel.

The construction methodology used was

- Bypass flow into the SPS

- Microtunnel directly into the collecting manhole at the SPS.

- Push pipes

- Form the grout retaining bulkheads and pour the grout.

Pipes

The Ø400mm pipes were conventional GRP pipes supplied by Global. The pipe joint was a rubber ring jointed collared pipe not a jacking pipe. The collared pipe is a less expensive pipe.

The pipes were held central in the microtunnel by timber spacers and were sliplined into the freebore without incident.

Progress

Microtunnelling commenced in July 2013 and was completed by the end of September 2013 including pipe insertion and grouting.

Launching the 530 microtunnelling head for the 139m bore.

All site setups were required to ensure passage of vehicles in Hickson Road

Global (Hobas) SN 10,000 collared pipes strapped and ready to be sliplined. The annular gap around the pipe was grouted.

All spoil had to remain on site. Decanting of the vacuum truck into specially prepared holding tanks.

MICROTUNNEL 1.

Free Pipe by Freebore Method

Length. 107m

Diameter. 530

Ground. Sandstone

Casing Pipe. None

Carrier Pipe. 375 GRP SN 10,000

MICROTUNNEL 2.

Free Pipe by Freebore Method

Length. 119m

Diameter. 530

Ground. Sandstone

Casing Pipe. None

Carrier Pipe. 375 GRP SN 10,000

MICROTUNNEL 3.

Free Pipe by Freebore Method

Length. 100m

Diameter. 530

Ground. Sandstone

Casing Pipe. None

Carrier Pipe. 375 GRP SN 10,000

MICROTUNNEL 4.

Free Pipe by Freebore Method

Length. 139m

Diameter. 6530

Ground. Sandstone

Casing Pipe. None

Carrier Pipe. 375 GRP SN 10,000

MICROTUNNEL 5.

Free Pipe by Freebore Method

Length. 137m

Diameter. 530

Ground. Sandstone

Casing Pipe. None

Carrier Pipe. 375 GRP SN 10,000

MICROTUNNEL 6.

Free Pipe by Freebore Method

Length. 48m

Diameter. 375 / 440

Ground. Sandstone

Casing Pipe. None

Carrier Pipe. 225 PVC SN 10,000