PROJECT OVERVIEW.

Slip-lining Steel Culverts

A lot of major Hwy’s were constructed over creeks and rivers. Some of the smaller creek crossings were simply filled in and the creek flow maintained using culverts. One of the common materials used for creek crossings in those time (60’s 70’) were segmented corrugated steel culverts. While this was certainly the cutting-edge material of choice at those times, it certainly came with an inherently short lifespan. Now these culverts are getting close to their end-of-life stages (if not already passed).

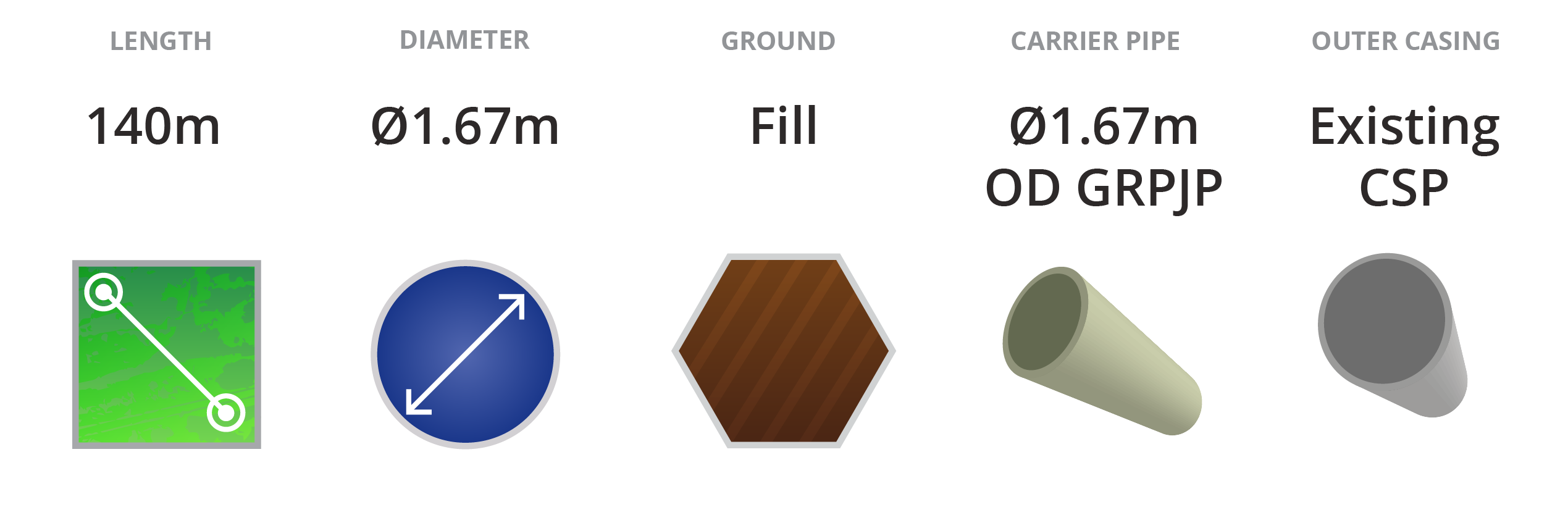

One of these examples is the NB2100 CSP (corrugated steel pipe) at Paddy’s River, approximately 10km south of Sally’s Corner.

This culvert was built in the late 60’s. Throughout the culvert various levels of deforming was visible and a number of weep holes. There was some works done in the culvert some 20 years ago where a concrete channel was formed along the invert.

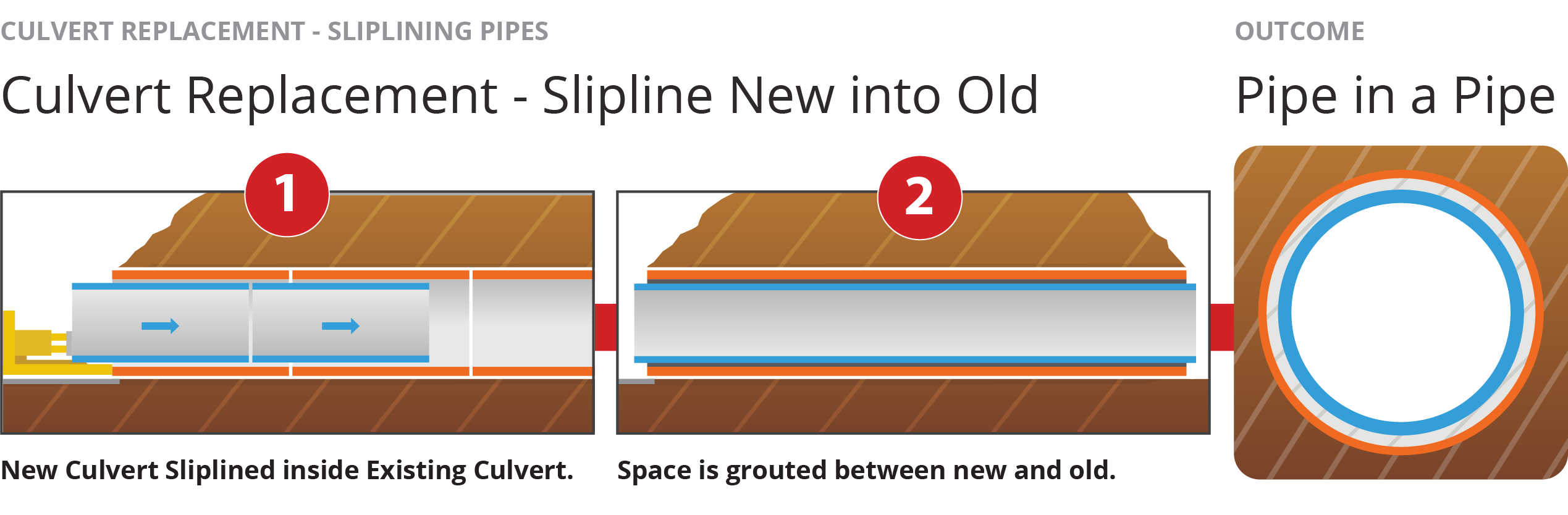

As part of the tender process, Pezzimenti proposed the existing culvert be slip lined with a thin GRP jacking pipe (flush collars) and the annulus grout filled.

This innovative solution was accepted by TfNSW and fun began.

Project Details

Being a remote site the Hume Hwy as the only access, deliveries of pipe, plant and other material required the slow lane and shoulder to be closed off to traffic. The access track from the Hwy to the pipe inlet, which would be our future launch area, was approximately 200m long and could only be trekked by an excavator.

Once the set down area and lunch area was ready, the creek was diverted form the launch station (jacking frame position).

The 1.67mOD GRPJP (3T each) were lowered and jacked from the jacking station. To ensure the integrity of the pipe, smooth metal angles were installed on the concrete channel edge. This not only protected the pipe barrel, it also provided for a lower friction factor, making the jacking process ‘effortless.

Once the pipes were slip-lined, we placed large blackouts on either end and commenced the 5day grout pour. A total of 98 cubic meters of grout was poured with the grout lines running down a 30m steep embankment.

As part of the demob, Pezzimenti rehabilitated the old access track and spray seeded the whole area to let nature take over.