PROJECT OVERVIEW.

Ground Conditions

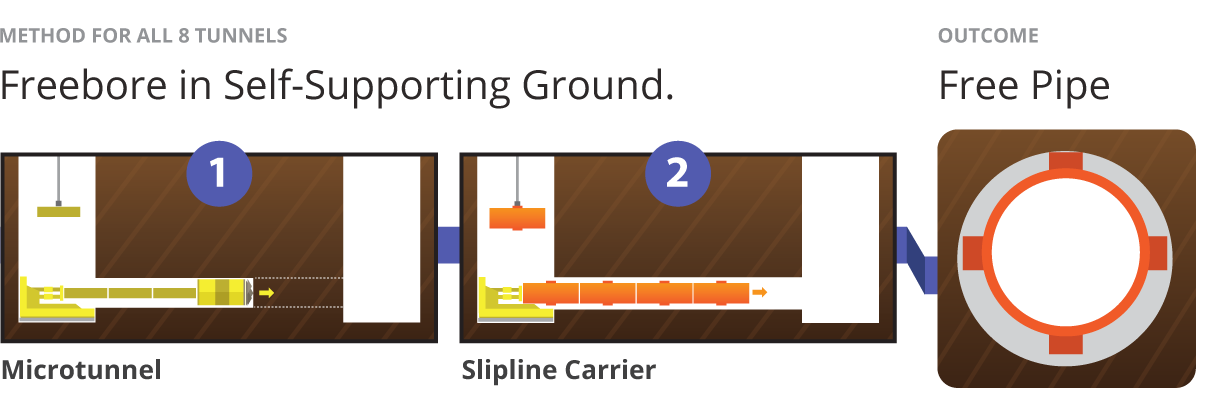

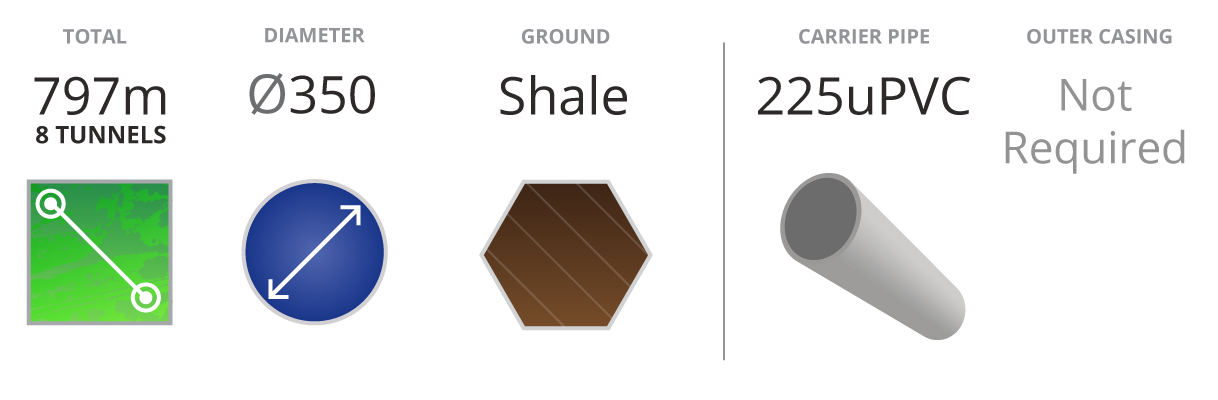

Pezzimenti tunnelbore found near perfect ground conditions at this microtunnelling project along Hollingsworth Road in Marsden Park – awarded by the client PWG. The self-supporting dry shale was highly favourable for tunnelling using the freebore method. With no water being required at the microtunnelling face, the spoil was left on site dry, saving the client significant spoil disposal costs.

The project was a great success – all 8 microtunnels were completed on line and grade, as well as being delivered 3 weeks ahead of schedule.

The depth of the lines, ranging from 4.5m to 8m, meant microtunnelling was the obvious choice over digging trenches; being both cost-effective and requiring no restoration to existing roads and services

92m Drive in a Single Day.

One of the microtunnels included a single drive length of 92 metres in one day – a company record for the most metres drilled in a day. Well done Andy.

Watch the Marsden Park Case Study Video

“Once we completed the first bore shaft, the 388m of boring and sewer pipe insertion was completed within 5 weeks including installing and grouting all of the pipes. The first section of the project went so well, substantially beating program, that PWG were then awarded the second stage by the client. This next stage included a further 427m of boring which was completed just as quickly and successfully… PWG are extremely pleased with Pezzimenti’s performance…. & would absolutely engage Pezzimenti in the future.”

~ Paul Ferguson

Managing Director PWG

MICROTUNNEL 1.

Free Pipe by Freebore Method

Length. 168m

Diameter. 375

Ground. Shale

Casing Pipe. N/A

Carrier Pipe. 225uPVC

MICROTUNNEL 2.

Free Pipe by Freebore Method

Length. 87m

Diameter. 375

Ground. Shale

Casing Pipe. N/A

Carrier Pipe. 225uPVC

MICROTUNNEL 3.

Free Pipe by Freebore Method

Length. 160m

Diameter. 375

Ground. Shale

Casing Pipe. N/A

Carrier Pipe. 225uPVC

MICROTUNNEL 4.

Free Pipe by Freebore Method

Length. 46m

Diameter. 365

Ground. hale

Casing Pipe. N/A

Carrier Pipe. 225uPVC

MICROTUNNEL 5.

Free Pipe by Freebore Method

Length. 82m

Diameter. 375

Ground. Shale

Casing Pipe. N/A

Carrier Pipe. 225uPVC

MICROTUNNEL 6.

Free Pipe by Freebore Method

Length. 140m

Diameter. 375

Ground. Shale

Casing Pipe. N/A

Carrier Pipe. 225uPVC

MICROTUNNEL 7.

Free Pipe by Freebore Method

Length. 97m

Diameter. 375

Ground. Shale

Casing Pipe. N/A

Carrier Pipe. 225uPVC

MICROTUNNEL 8.

Free Pipe by Freebore Method

Length. 17m

Diameter. 375

Ground. Shale

Casing Pipe. N/A

Carrier Pipe. 225uPVC