PROJECT OVERVIEW.

Overcoming very Hard Concrete and Steel

The gravel for the concrete for the dam had been sourced from the local river gravel and these had strengths over 100MPa. Encountering steel reinforcement was always a possibility. Steel reo was encountered once – within 1m of the start and this was removed using core drilling.

Drilling proceeded over a period of 2 weeks with adjustments to the head necessary due to the hardness of the concrete.

Flexibility of Pezzimenti Site Setup at Dam

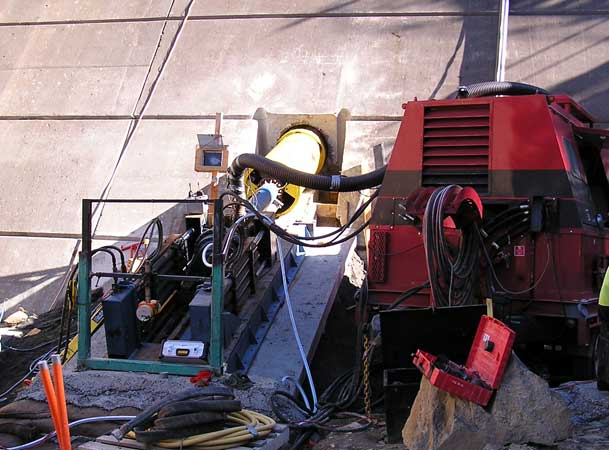

The jacking frame had to be set up 30m below the dam crest on a concrete plinth poured on the design grade of 35%. The plinth was designed with the thrust block bearing on natural ground.

The hydraulic power pack was lowered into place at the base of the dam near the jacking frame by the site’s tower crane. The vacuum power pack was stationed on the crest wall and the vacuum suction line was lowered the 30m down the face of the dam to connect the jacking frame to the vacuum unit.

Site tower crane lowers the microtunnelling head into position

Lowering of the 1000mm diameter head down the face of the dam wall

View from the dam crest

Slipling of the steel carrier pipe into the dam wall

Closeup of carrier pipe showing steel spacers welded to the outside of the pipe.

Launching of the microtunnelling head

Launch pad showing hydraulic power pack, the microtunnelling head, jacking frame and laser bar frame

The vacuum power unit was kept on the dam crest road

Microtunnelling under way, note the vacuum suction line in the background.