The top section around the shaft was benched to reduce the shoring section to 6m deep.

Craneage was supplied by Mystold’s excavator

Launching the 750m diameter microtunnelling head

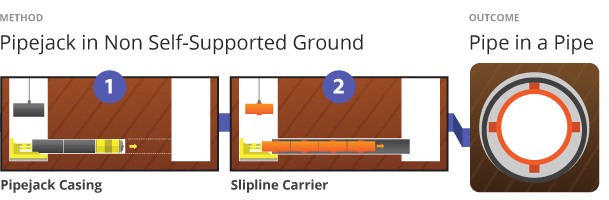

The completed product a 600 PP pipe inside a 750 butt jointed RC jacking pipe.