PROJECT OVERVIEW.

Micotunneling beneath a Railway

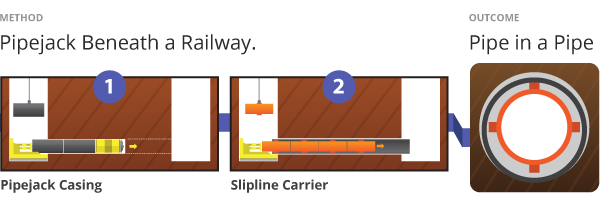

As the microtunnel was below a rail line, the outer casing had to be pipe jacked and could not be steel. Thus a 600 GRP jacking pipe was nominated as the casing. This allowed for a smaller diameter microtunnel to be used and effectively meant a quicker bore and less spoil.

Being a rail bore, the work had to be performed during a rail shutdown weekend – normal hours 3am Saturday morning to 5pm Sunday evening. Pezzimenti tunnelbore were allowed to get established prior to the shutdown and bore up to the rail fence line. We had two crews ready to work around the clock to complete the bore.

Completing the Pipejack

The bore was completed by the first shift by 5pm Saturday afternoon leaving the second night crew to pull out the head from the opposite side and retract the rods back through the GRP jacking pipe.

A Track Protection Officer was vigilant and checking track condition at regular intervals during micro tunnelling operation. There was zero track settlement.

Pezzimenti tunnelbore received praise from both the client and Endeavour Energy who were quite nervous about the work being completed in time.

Craning the outer casing GRP Jacking Pipes at the entry shaft

Preparing GRP pipes for pipejacking.

Pipejacking the GRP Pipes

V4 unloading spoil.

Drill head successfully break through at the exit pit

Track Protection Officer was vigilant and checking track condition at regular interval during micro tunnelling operation

The microtunnelling head is detatched from the drill rods before being removed via the exit shaft. The drill rods were then pulled back through the GRP Jacking Pipes and removed. Then PVC Conduits were sliplined into the GRP Jacking Pipes.

The Microtunnelling Head is removed from the exit shaft after microtunnelling 40m beneath the railway lines.

MICROTUNNEL 1.

Free Pipe by Freebore Method

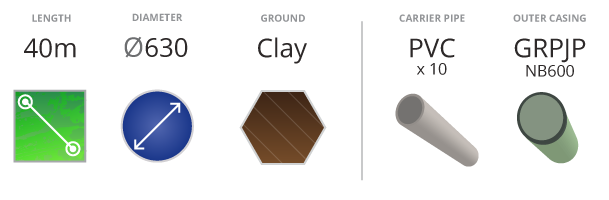

Length. 40m

Diameter. 630

Ground. Clay

Casing Pipe. NB600 GRPJP

Carrier Pipe. 450 GRP JP