Project Overview

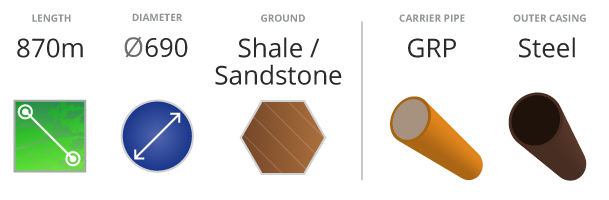

The total length of the line required 870 lineal metres of 450mm diameter GRP pipe encased with a Ø660 steel casing. The maximum length of a single drive was 180m. The grade was designed at the very flat value of 0.240%. Lend Lease awarded the works which included open cut sections to Trazlbat. Trazlbat subcontracted the microtunnelling to Pezzimenti Tunnelbore.

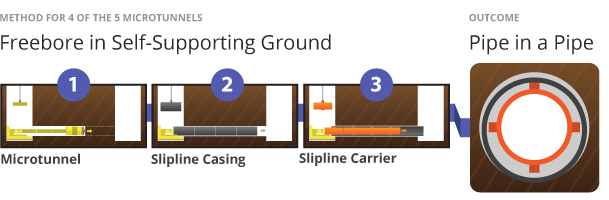

Self-Supporting Ground Conditions

The ground was a weathered shale to clay. The first 4 microtunnels were created using the freebore method, then the steel casing was inserted, followed by the pipes and the annular void grouted. The last bore in clay was pipejacked to maintain stability of the bore during microtunnelling.

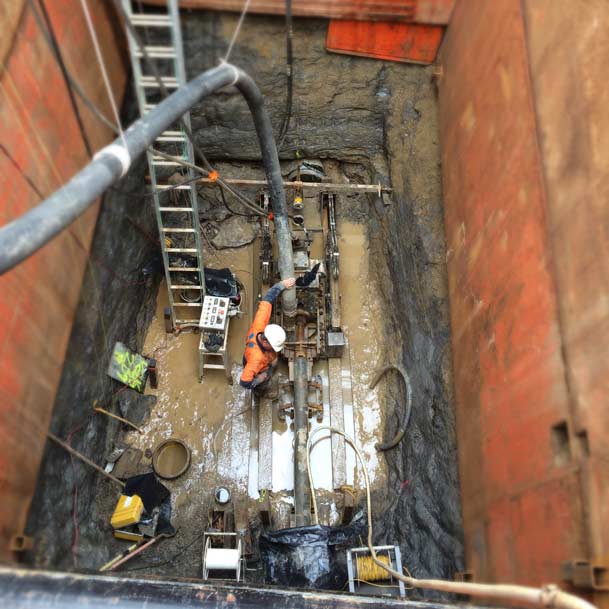

Site Set-up: The top section of the ground was cut down to allow excavation of the lower 6 metres of the shaft.

Freeboring in shale

Piepejacking the steel casing in ground which was not self-supporting.

Sliplining a SN20,000 GRP collared Pipe

MICROTUNNEL 1.

Pipe in a Pipe by Freebore Method

Length. 175m

Diameter. 690

Ground. Sandstone / Shale

Casing Pipe. 660 Steel

Carrier Pipe. 450 GRP SN20K

Grade 0.26%

MICROTUNNEL 2.

Pipe in a Pipe by Freebore Method

Length. 145m

Diameter. 690

Ground. Sandstone / Shale

Casing Pipe. 660 Steel

Carrier Pipe. 450 GRP SN20K

Grade. 0.26%

MICROTUNNEL 3.

Pipe in a Pipe by Freebore Method

Length. 175m

Diameter. 690

Ground. Sandstone / Shale

Casing Pipe. 660 Steel

Carrier Pipe. 450 GRP SN20K

Grade. 0.26%%

MICROTUNNEL 4.

Pipe in a Pipe by Freebore Method

Length. 174m

Diameter. 690

Ground. Sandstone / Shale

Casing Pipe. 660 Steel

Carrier Pipe. 450 GRP SN20K

Grade 0.24%

MICROTUNNEL 5.

Pipe in a Pipe by Pipejack Method

Length. 176m

Diameter. 690

Ground. Clay / Shale

Casing Pipe. 660 Steel

Carrier Pipe. 450 GRP SN20K

Grade. 0.24%