PROJECT OVERVIEW.

Pipejack and Freebore

Both pipejacking and freeboring techniques were used depending on the ground conditions. The ground conditions varied from saturated clay (N=5) to Hawkesbury Sandstone UCS=50MPa. Pezzimenti Tunnelbore completed works by directly for Lend Lease managing the construction of the shafts as well as working as a specialist subcontractor for Diona P/L which was a major contractor.

Microtunnel into a Manhole.

Of note was a Ø800 core drill into the collecting MH of a live sewerage pump station. The collecting MH is 12m deep and there was concern that excavation around the manhole for a standard connection would weaken the structure. Pezzimenti Tunnelbore proposed a solution based on previous works to core into the structure from a jacking shaft some 20m away. The coring process minimised vibration during the cut-in.

Site set-up inside an 11m deep shaft to microtunnel 52m x 1130mm diameter microtunnel, pipejacking a 900 diameter J-series RCJP.

900mm diameter J-Series Reinforced Concrete Pipes pipejacked beneath the railway.

Operator monitors the equipment as Pipejacking beneath the railway commences. Looking down into the shaft at Work Lot 6.

Microtunneling was utilised at work lot 20 to preserve environmental areas including those with Aboriginal Significance, beneath a creek and below a rocky outcrop.

Down the shaft at Work Lot 20, Pipejacking commences. This 15m microtunnel would cross beneath a creek bed.

MICROTUNNEL 1.

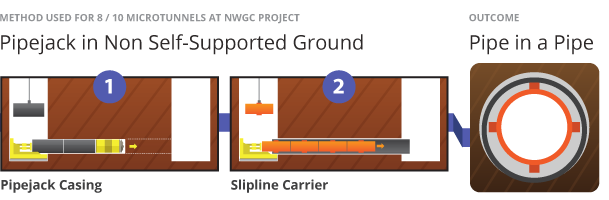

Pipe in a Pipe by Pipejack Method

Length. 203m

Diameter. 530mm

Ground. Clayey Sand

Casing. 508 Steel

Carrier. 300 GRP

Grade. 0.30%

MICROTUNNEL 2.

Pipe in a Pipe by Pipejack Method

Length. 180m

Diameter. 530mm

Ground. Clayey Sand

Casing. 508 Steel

Carrier. 300 GRP

Grade. 0.30%

MICROTUNNEL 3.

Pipe in a Pipe by Pipejack Method

Length. 156m

Diameter. 530mm

Ground. Clayey Sand

Casing. 610 Steel

Carrier. 400 GRP

Grade. 0.45%

MICROTUNNEL 4.

Pipe in a Pipe by Pipejack Method

Length. 155m

Diameter. 630mm

Ground. Clayey Sand

Casing. 610 Steel

Carrier. 400 GRP

Grade. 0.45%

MICROTUNNEL 5.

Pipe in a Pipe by Pipejack Method

Length. 162m

Diameter. 630mm

Ground. Clayey Sand

Casing. 610 Steel

Carrier. 400 GRP

Grade. 0.45%

MICROTUNNEL 6.

Free Pipe by Freebore Method

Length. 52m

Diameter. 560mm

Ground. Sandstone

Casing. None

Carrier. 450 SN10K GRP

Grade. 0.5%

MICROTUNNEL 7.

Pipe in a Pipe by Pipejack Method

Length. 15m

Diameter. 780mm

Ground. Sat. Alluvials

Casing. 762 Steel

Carrier. SN20K GRP

Grade. –0.4%

MICROTUNNEL 8.

Free Pipe by Freebore Method

Length. 145m

Diameter. 700mm

Ground. Sandstone

Casing. None

Carrier. 525 SN20K GRP

Grade. 0.4%

MICROTUNNEL 9.

Free Pipe by Freebore Method

Length. 20m

Diameter. 815mm

Ground. Sandstone

Casing. 800 Steel

Carrier. 525 SN20K GRP

Grade. –0.4%

MICROTUNNEL 5.

Pipe in a Pipe by Pipejack Method

Length. 52m

Diameter. 1130mm

Ground. Shale

Casing. 900 J RC

Carrier. 800 PE

Grade. 14.1%