Long Distance Microtunnelling Capability

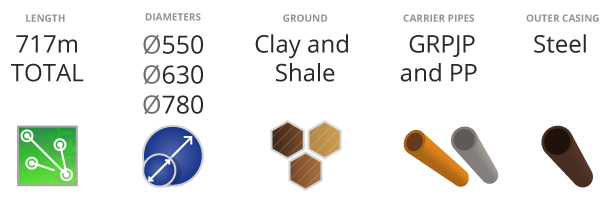

In all the works required the installation by microtunnelling of 782 lin metres Ø225, 300 and 375 PVC encased by steel casing pipe. The drive lengths were 170m, 120m, 185m 132m & 175m.

Pezzimenti Tunnelbore were awarded the works by Zinfra P/L. The works were designed by Qalchek.

Project Details

The ground conditions were shale and clay. On two of the runs high plasticity clay was encountered which slowed progress considerably.

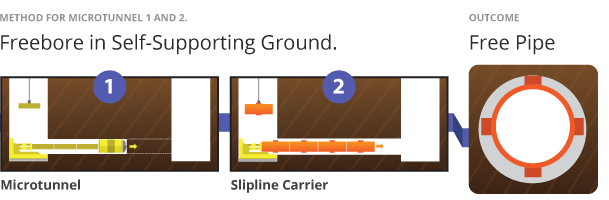

In all progress achieved was 20-30m per day for the drilling. Freeboring was carried out wherever possible to hasten the process and to change the cutters as required in the highly variable ground conditions.

Typical shaft setup in close proximity to the operating golf course.

Freeboring in Clayey Shale

300 Diameter RRJ PVC Pipes strapped with timber

Breakthrough of the microtunnelling head into the exit shaft.

MICROTUNNEL 1.

Free Pipe by Freebore Method

Length. 170m

Diameter. X

Ground. Shale & Clay

Casing Pipe. Steel

Carrier Pipe. PVC

MICROTUNNEL 2.

Free Pipe by Freebore Method

Length. 120m

Diameter. X

Ground. Shale & Clay

Casing Pipe. Steel

Carrier Pipe. PVC

MICROTUNNEL 3.

Pipe in a Pipe by Pipejack Method

Length. 185m

Diameter. X

Ground. Shale & Clay

Casing Pipe. Steel

Carrier Pipe. PVC

MICROTUNNEL 4.

Pipe in a Pipe by Pipejack Method

Length. 132m

Diameter. X

Ground. Shale & Clay

Casing Pipe. Steel

Carrier Pipe. PVC

MICROTUNNEL 5.

Pipe in a Pipe by Pipejack Method

Length. 175m

Diameter. X

Ground. Shale and Clay

Casing Pipe. Steel

Carrier Pipe. PVC