Completed Freebore is Self Supporting Sandstone

The rods during microtunneling using the Freebore Method

Inside the freebore which was completed in very hard rock.

Freeboring Microtunneling Methods

There are 3 primary outcomes for all microtunneling and pipe installations. These are the

- Free Pipe – Carrier Pipe is grouted into a microtunneling where the ground is self supporting.

- Close Fit Pipe – Carrier Pipe is also the Casing Pipe. Use for projects where the gap between Pipe OD and Microtunnel ID is less than 25mm, and;

- Pipe-in-a-Pipe – A carrier Pipe sits within an Outer Casing Pipe.

Freebore Microtunneling method can achieve them all as outlined below.

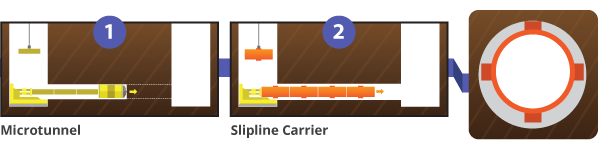

Free Pipe Method.

Step 1. The ground has been determined to be self-supporting and is microtunnelled without the need for ground support. Step 2. The Carrier Pipe is sliplined into the microtunnel and the annulus space is grouted.

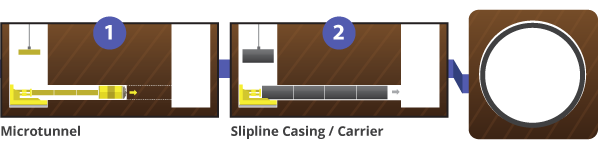

Close-Fit Pipe – Freebore Method

Step 1. The ground has been determined to be self supporting and is microtunnelled without the need for ground support. Step 2. The Casing Pipe, which is also the carrier pipe, is sliplined into the microtunnel. Ideal for designs where the between the Casing Pipe OD and the Microtunnel is < 25mm.

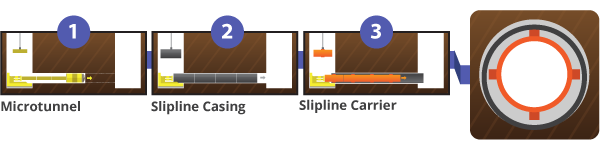

Pipe in a Pipe – Freebore Method

Step 1. The ground has been determined to be self supporting and is microtunnelled without the need for ground support. Step 2. The Casing Pipe is sliplined into the microtunnel. Step 3. The carrier Pipe is sliplined into the casing pipe.

Freebored Projects

View a selection of projects which include freebore microtunnelling.