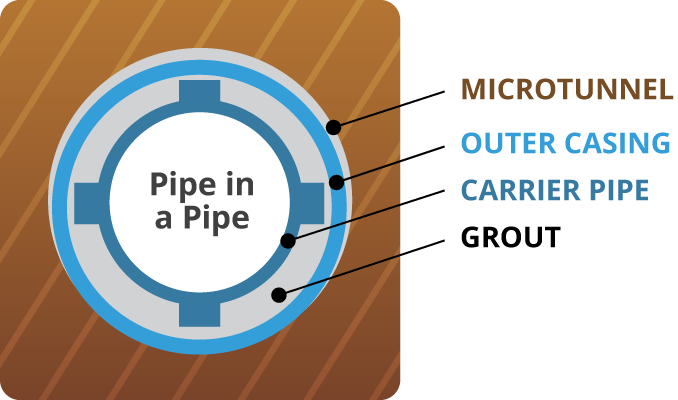

Pipe in a Pipe with a Temporary Outer Casing

The methodology below shows how pezzimenti utilises a retractable microtunnelling head for the Pipe in a Pipe Bore Section – where a carrier pipe is sliplined into an outer casing pipe.

+ Pipe in a Pipe Bore Section

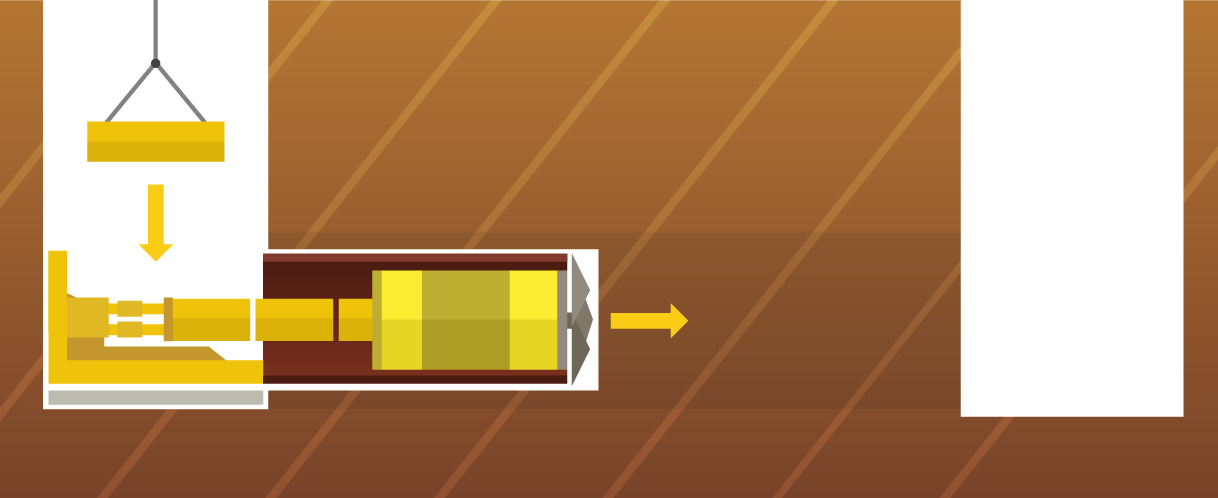

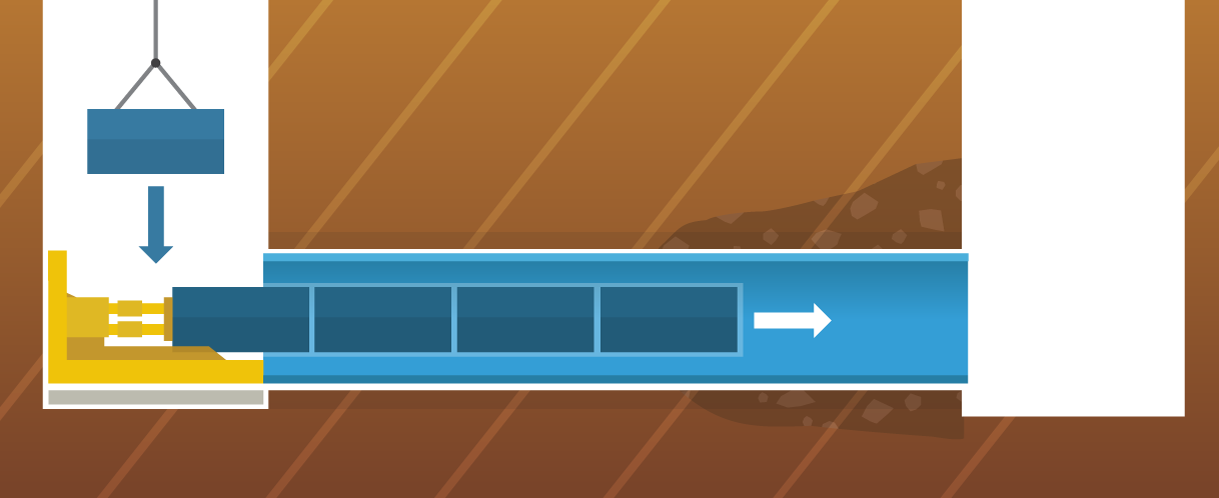

01. Microtunnel

The retractable microtunnelling head is launched from the entry shaft inside the first sleeve.

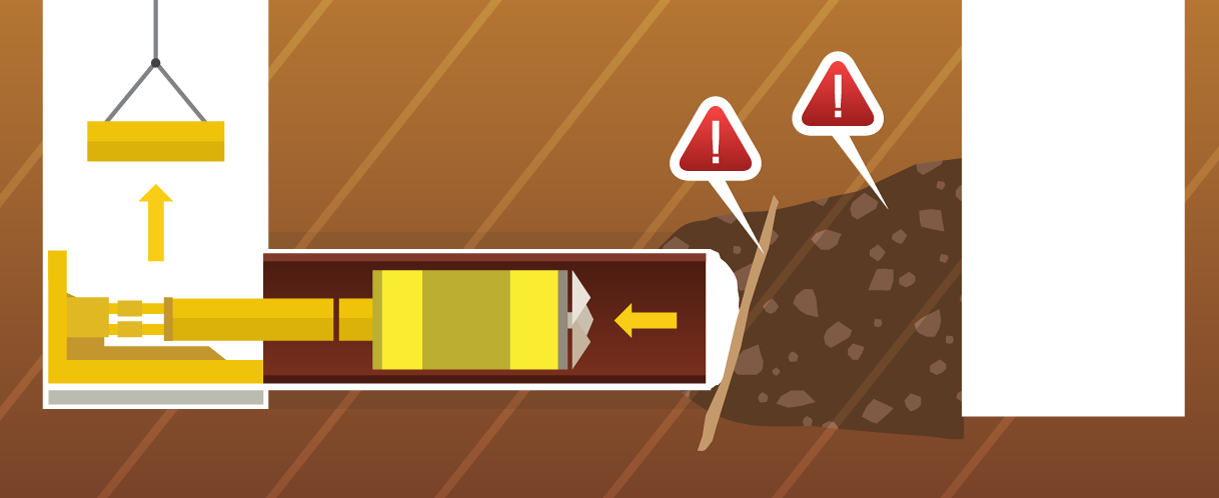

02. An Obstruction Encountered

In the event that an an obstruction is encountered, ground conditions change or the head requires repair – the microtunnelling head can be retracted – while the outer casings remain in place to support the ground.

03. Situation Remedied

Once the Obstruction has been removed, the Cutters replaced to match ground condition or the microtunnelling head has been repaired – the microtunnelling head is pushed back to the face and microtunnelling recommenced.

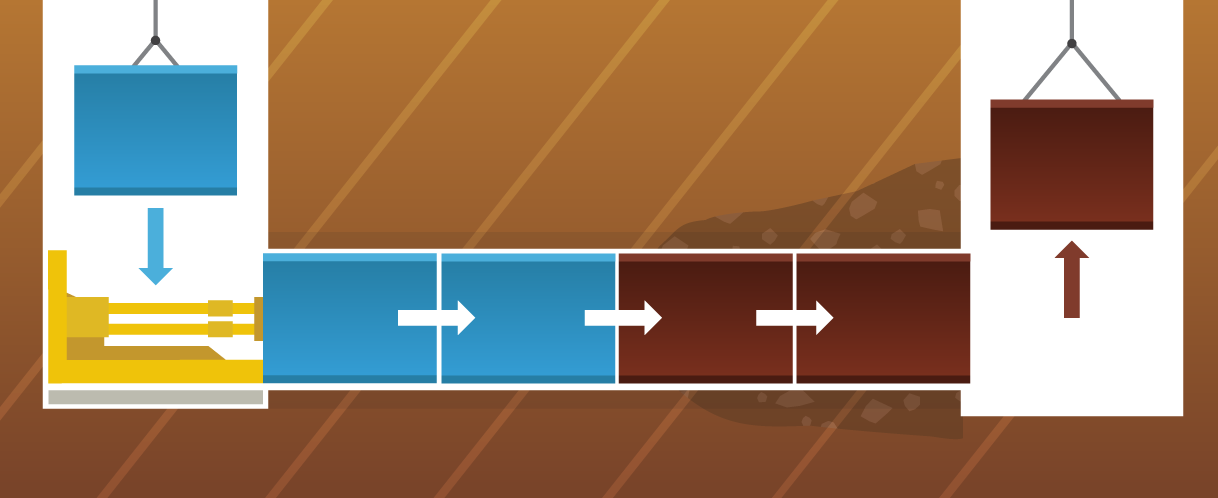

04. Bore Completed

The microtunnelling head can be removed via the exit Shaft OR retracted back to the launch shaft. Outer casing is now in place.

05. Recycle the Outer Casings

The permanent outer casing pipes are jacked in to replace the temporary outer casings, e.g. temporary steel casings are replaced by concrete pipes under a railway line

06. Slipline the Carrier Pipe

The carrier can is now sliplined into the outer casing and the annulus grouted as required. Microtunnel complete.

Book a Presentation

For futher information on Retractable Microtunelling Head Capabilities and Methodologies book a presentation for your design team with Pezzimenti today. Call Scott Wells on: +61 (2) 4735 6676 or email scott.wells@pezzimenti.com.au