Close Fit Pipe

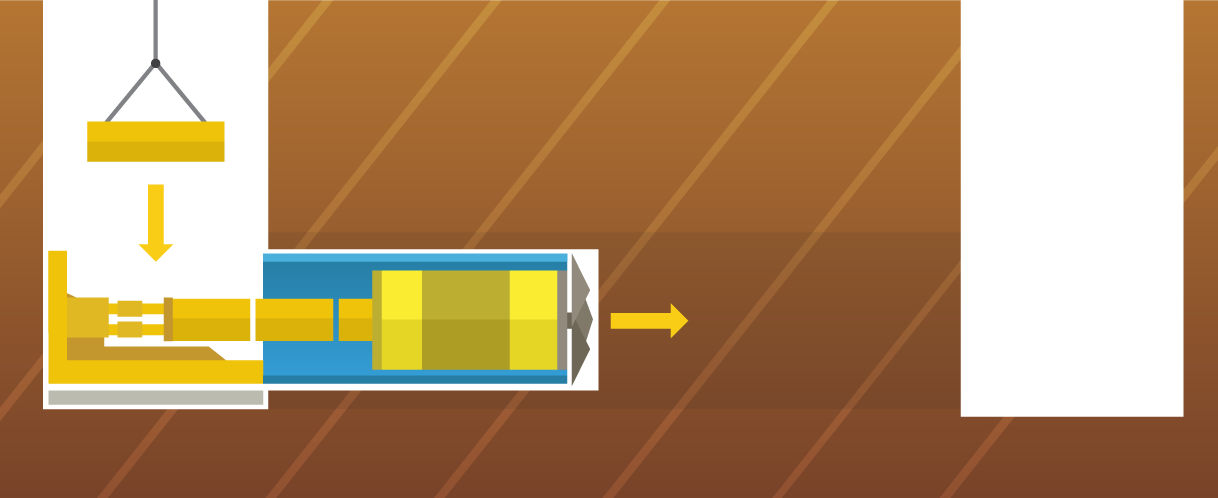

The methodology below shows how pezzimenti utilises a retractable head for the Close-Fit Bore

Section, e.g. for:

• Temporary Steel GRP Jacking Pipe for sewer

• Temporary Steel Concrete Jacking Pipe for stormwater

+ Close Fit Pipe Bore Section

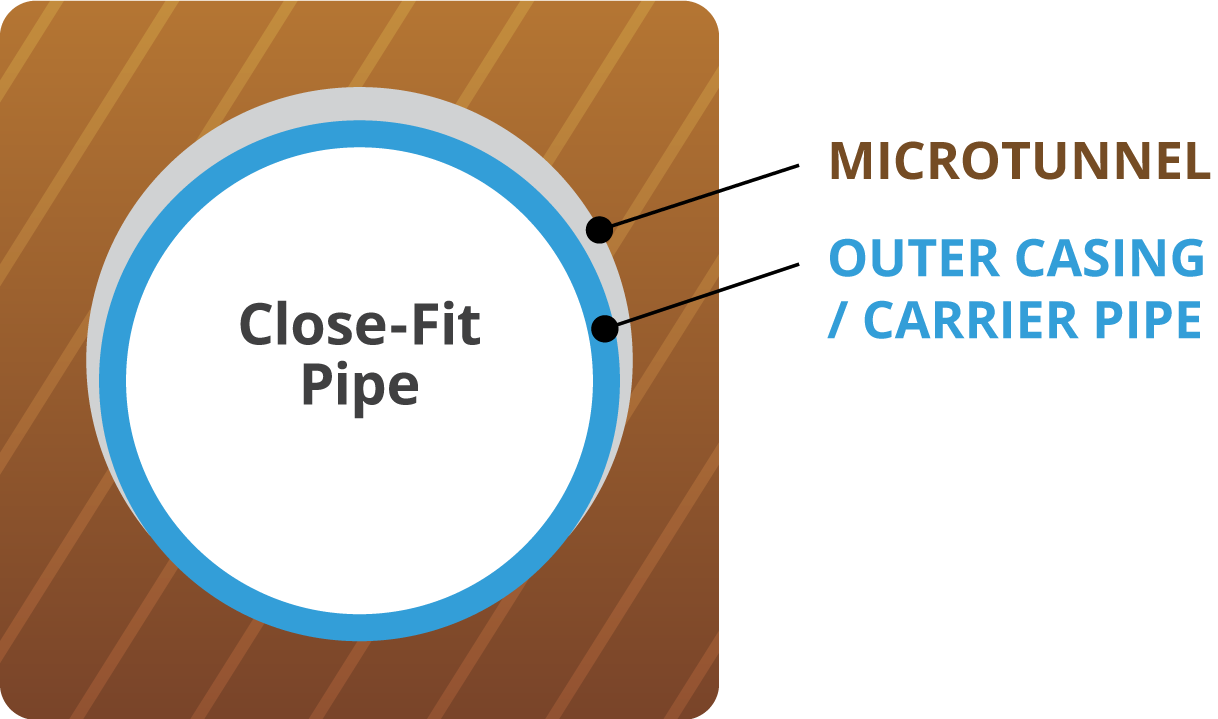

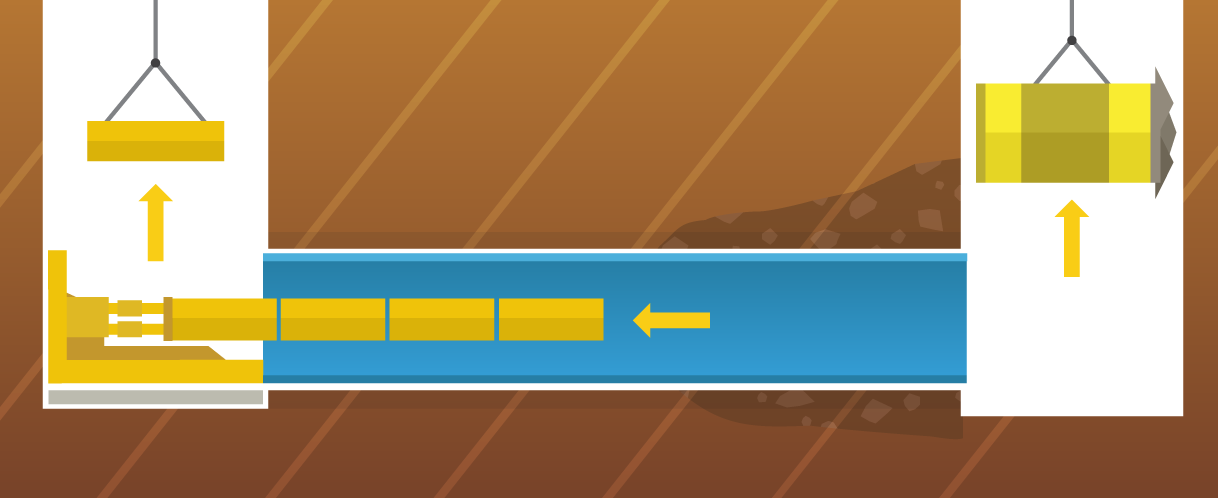

01. Microtunnel

The retractable microtunnelling head is launched from the entry shaft inside the first sleeve.

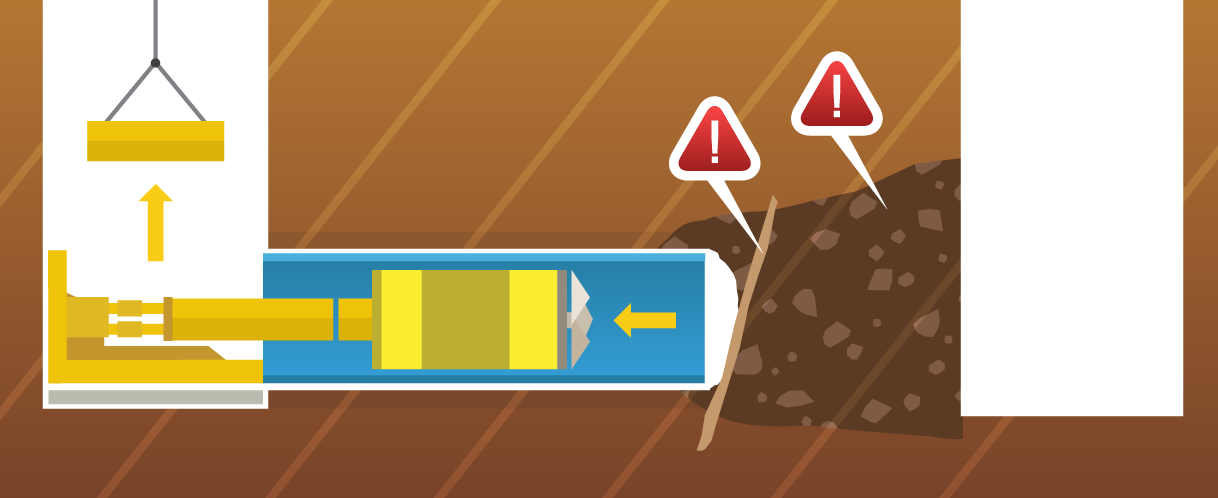

02. An Obstruction Encountered

In the event that an an obstruction is encountered, ground conditions change or the head requires repair – the microtunnelling head can be retracted – while the outer casings remain in place to support the ground.

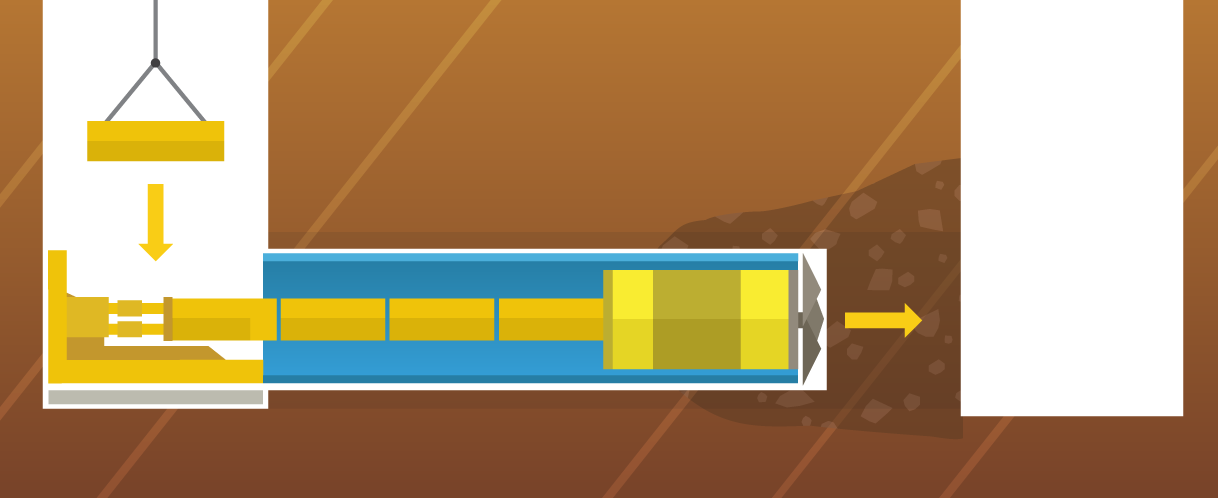

03. Situation Remedied

Once the Obstruction has been removed, the Cutters replaced to match ground condition or the microtunnelling head has been repaired – the microtunnelling head is pushed back to the face and microtunnelling recommenced.

04. Complete the Bore

To the exit shaft and remove the head OR retract the head back to the launch shaft.

05. Bore Complete

Outer casing / carrier is in place.

Book a Presentation

For futher information on Retractable Microtunelling Head Capabilities and Methodologies book a presentation for your design team with Pezzimenti today. Call Scott Wells on: +61 (2) 4735 6676 or email scott.wells@pezzimenti.com.au