Retractable Microtunnelling Heads

Retractable Heads and cutters can be bought back to the shaft when pipejacking in case of:

- Obstruction eg filled ground, rock anchors, services, cobbles

- Major change in ground conditions – e.g clay to sandstone which would require different cutters

- Vacuum blockage which can be encountered in high plasticity clay or sand

Thus, eliminating the need to salvage a bore via an intercept or head excavation

Retractable Head Methodologies

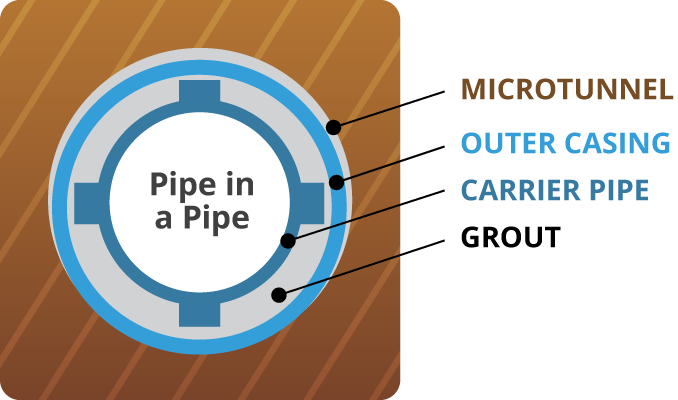

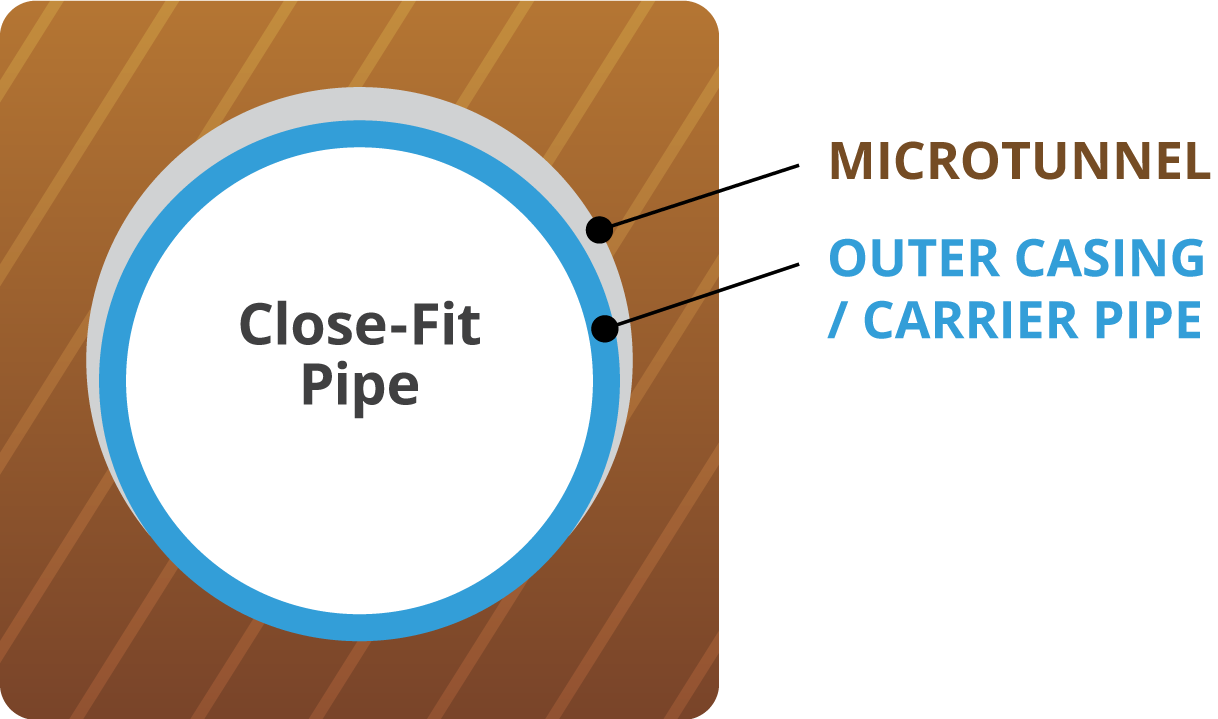

Retractable Microtunnelling heads can be utilised for both the Pipe in a Pipe, and Close-Fit Pipe Bore Sections. Where required, a temporary outer casing can be used for both bore sections, which is then Pipejacked out later.

The Pipe in a Pipe Bore Section methodology is shown as an example below. Clicking the blue buttons below each bore section will allow you to view the other methods for each section.

+ Methodology shown below is for the Pipe in a Pipe Bore Section

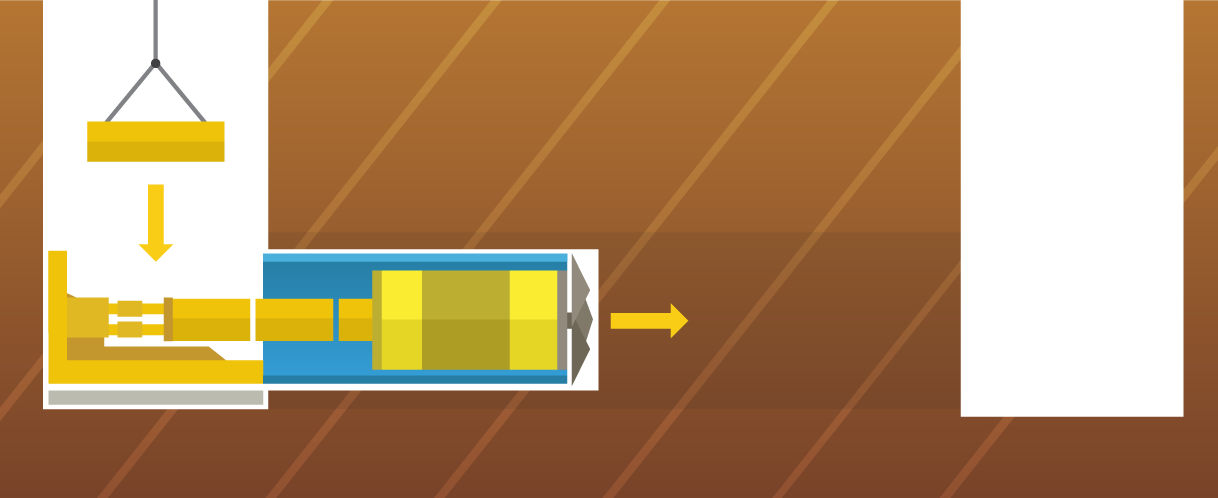

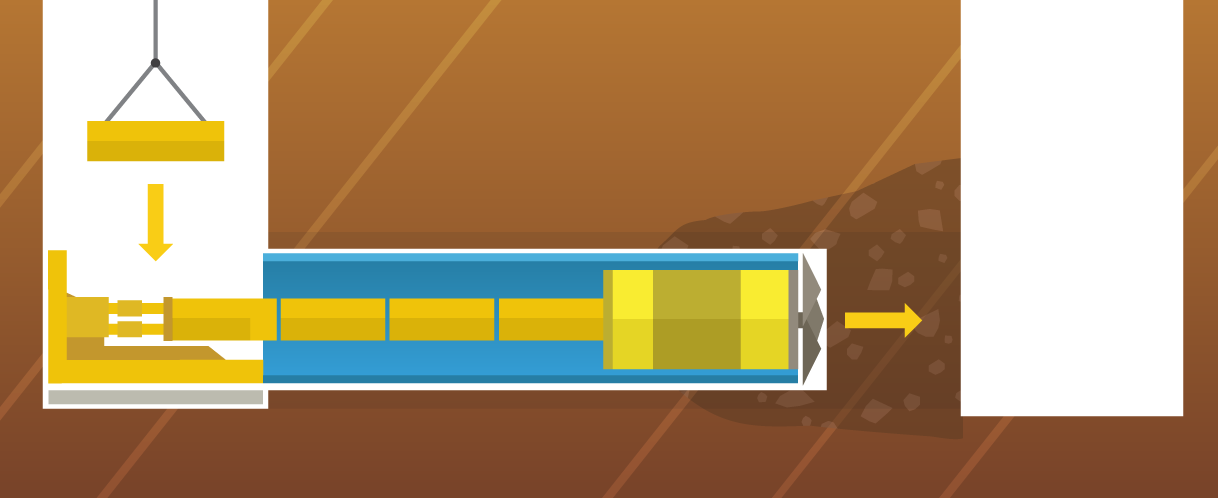

01. Microtunnel

The retractable microtunnelling head is launched from the entry shaft inside the first sleeve.

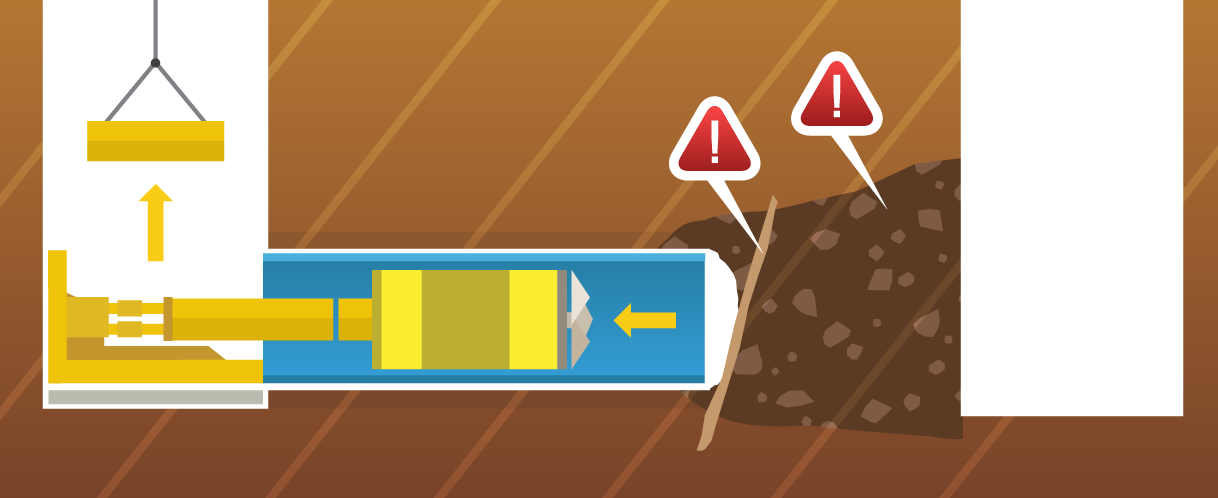

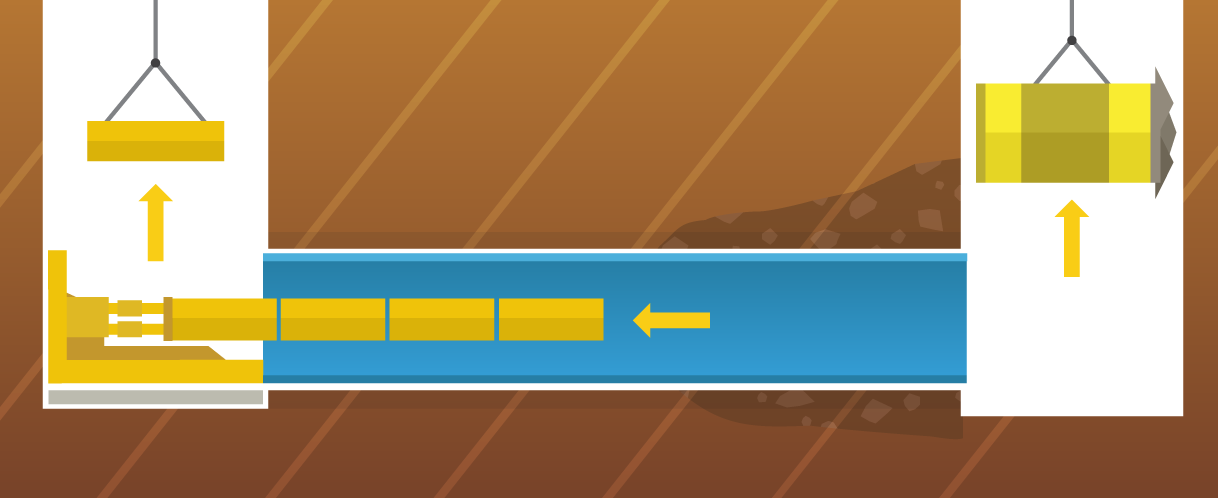

02. An Obstruction Encountered

In the event that an an obstruction is encountered, ground conditions change or the head requires repair – the microtunnelling head can be retracted – while the outer casings remain in place to support the ground.

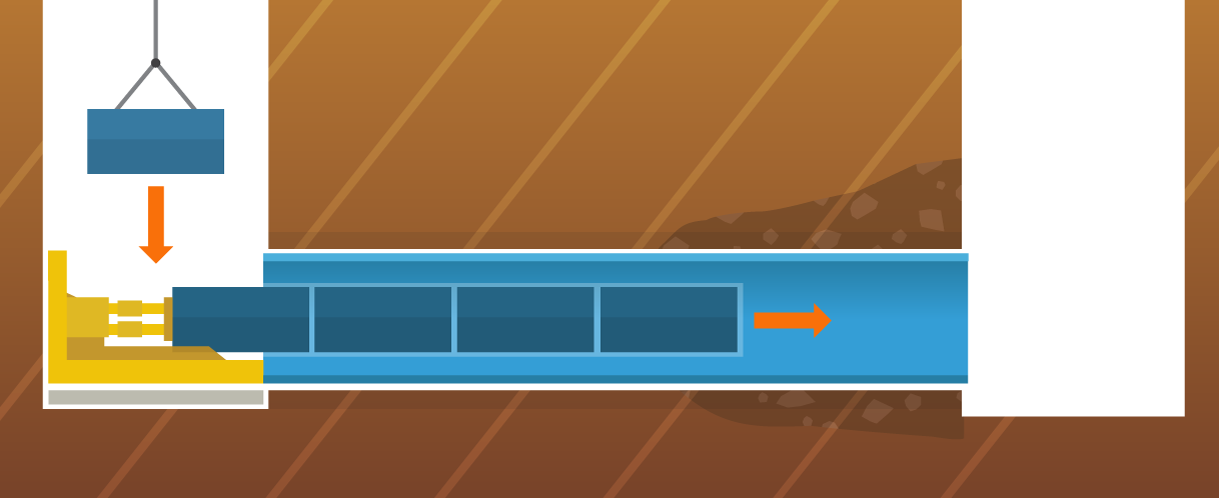

03. Situation Remedied

Once the Obstruction has been removed, the Cutters replaced to match ground condition or the microtunnelling head has been repaired – the microtunnelling head is pushed back to the face and microtunnelling recommenced.

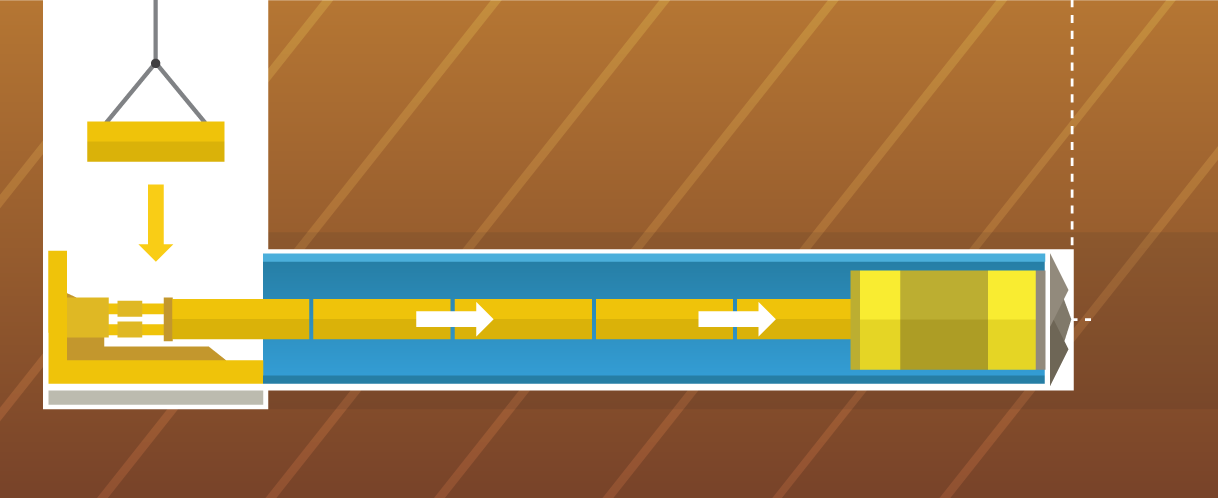

04. Bore Completed

The microtunnelling head can be removed via the exit Shaft OR retracted back to the launch shaft. Outer casing is now in place.

05. Slipline the Carrier Pipe

The carrier can is now sliplined into the outer casing and the annulus grouted as required. Microtunnel complete.

No Exit Shaft Required

A major advantage of the retractable head microtunnelling system is that no exit shaft is required when the work is commenced. This allows microtunnelling to be planned for completion outside of project pressures and time constraints, and may significantly reduce overall project costs – with no exit shaft needing to be secured, maintained or traffic controlled utilised, until absolutely necessary.

+ Retractable Microtunnelling Head Projects

Marsden Park

Ground Condition Change

A change of ground condition from Clay to Shale at this RMS Road crossing in Marsden Park required the microtunnelling head to be retracted. The cutters were replaced and microtunnelling recommenced with minimal project downtime.

Wyee

Under Railway

Retractable Heads were used on both bores at the simultaneous Rail Crossings at Wyee on the NSW Central Coast during one 48 hour weekend shutdown. Both 440mm diameter bores involved pipejacking a DN427 GRP Jacking Pipe.

Austinmeer

No Exit Shaft

A 26m, 830mm diameter tunnel with no retrieval access available at the exit end was required at this project in Austinmer. Retractable Cutters were fabricated, with the design enabling the microtunnelling head to be retracted to the launch shaft after breakthrough at the exit end leaving behind the carrier pipe.

Pymble

Into Manhole Base

Retractable Cutters and laser guided accuracy were utilised to core into a manhole base on this project at Pymble. After microtunnelling 19m in clay and fill the head was retracted back to the launch shaft. A corer then replaced the cutters and was used to break into the manhole.

Book a Presentation

For futher information on Retractable Microtunelling Head Capabilities and Methodologies book a presentation for your design team with Pezzimenti today. Call Scott Wells on: +61 (2) 4735 6676 or email scott.wells@pezzimenti.com.au