PROJECT OVERVIEW

Project Details

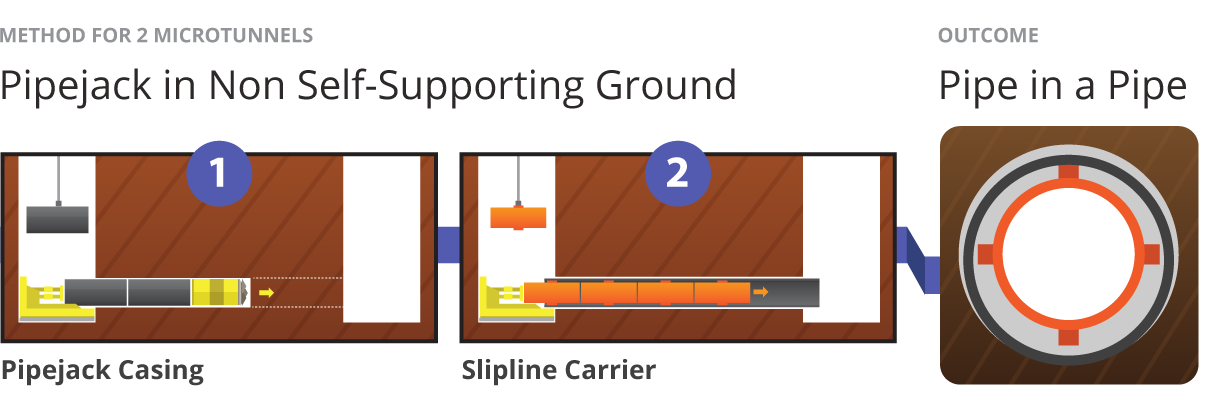

Both 440mm diameter bores involved pipejacking a steel casing and installing a Clover Pipelines DN427 GRP Jacking Pipe. One bore was in hard conglomerate 85m long and the other 64m in clay.

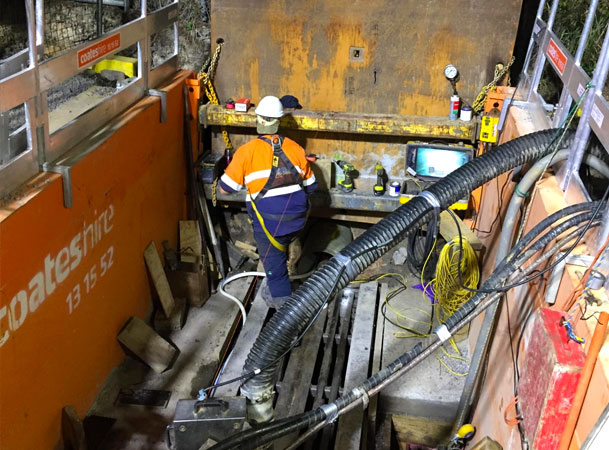

Retractable heads were used on both bores. This system enabled Pezzimenti to retrieve the head and cutters through the enveloper pipe in the event of a change of ground conditions or if an obstacle was struck.

Rail shutdown bores present several challenges. Given the short timeframes for completion, everything becomes hyper-critical. Confidence in equipment, staff and processes is essential. Precise planning and co-ordination is required to ensure a successful outcome.

Preparation commenced setting up on the Wednesday and Pezzimenti were ready for the shutdown to start 2am on Saturday morning.

The client allowed Pezzimenti to bore up to the track ‘critical zone’ prior to the commencement of the rail shutdown. This helped minimise the number of metres to be bored during the shutdown.

Both bores successfully punched through with plenty of time to spare despite the wet weather – the first at 11pm Saturday night and the second Sunday around midday.

As the casing was installed, there was no need to install the carrier pipe during the shutdown, however the guys did anyway, ready for it to be grouted up during the next week.

Successfully completing the two rail bores well within the shutdown period is a terrific achievement.

MICROTUNNEL 1.

Pipe in a Pipe by Pipejack Method

Length. 147m

Diameter. 630

Ground. Clay / Shale

Casing Pipe. 610 Steel

Carrier Pipe. 375 PP

MICROTUNNEL 2.

Pipe in a Pipe by Pipejack Method

Length. 82m

Diameter. 630

Ground. Clay/Shale

Casing Pipe. 610 OD Steel

Carrier Pipe. 375 PP