PROJECT OVERVIEW.

Long distance capability eliminates manholes.

Menangle Rd is a busy, two lane arterial road joining Menangle Park and Campbelltown. Menangle. The pipe alignment followed an existing VC pipe which was under capacity. It essentially followed the verge of the road and at times beneath the road pavement. Ground conditions were favourable being self-supporting shale, which allowed microtunnelling extended distances. This minimised the number of bends required in the line and also negated the need for change of direction manholes.

Roadside Site Setup that maintains traffic flow

The shafts were dug adjacent to the road pavement meaning Pezzimenti’s container trucks setup on line with the pipe were ideal – also considering the overhead wires in the vicinity – with no overhead cranage allowed. The power pack is inside the container truck itself so it is ideal for tight areas. The vacuum and slurry bins were setup on the other side of the shaft also in line with the pipeline keeping the work area as narrow as possible. This setup allowed the project to be completed without any lane closures an maximised traffic flow.

Roadside microtunnelling – capability to set the trucks up inline allowed the busy road to stay open.

Site Setup – A vacuum truck is ready to transport spoil.

The Gantry truck and hook lift truck paralell beside Mengangle Road

Lowering the 434 GRP JP Pipes to be sliplined into the completed microtunnel. The crane and gantry truck worked side by side in the tight space to allow continual traffic flow.

Drill rod is lowered to the jacking frame during microtunnelling

Operator controls the jacking frame to drop drill rod into position

Sliplining the 434 GRPJP carrier pipe into the microtunnel

Hook Lift Truck and the Container Truck roadside, without impacting traffic flow.

Down into shaft.

Operator Andy connects Vacuum hose to spoil capture bin.

The 434 GRPJP were sliplined into the microtunnel, which was self-supporting shale.

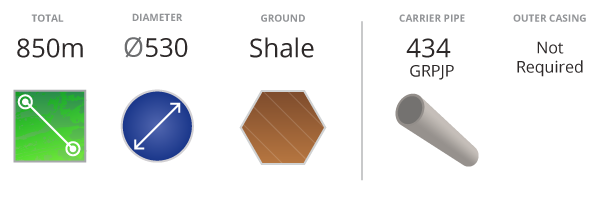

MICROTUNNEL 1.

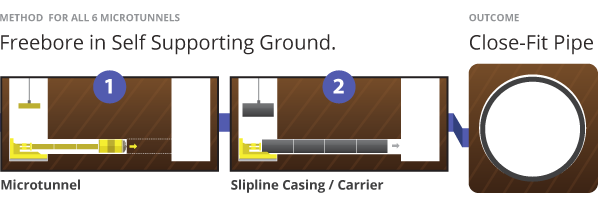

Close Fit Pipe by Freebore Method

Length. 163m

Diameter. 530

Ground. Shale

Casing Pipe. None

Carrier Pipe. 434 GRP JP

MICROTUNNEL 2.

Close Fit Pipe by Freebore Method

Length. 126m

Diameter. 530

Ground. Shale

Casing Pipe. None

Carrier Pipe. 434 GRP JP

MICROTUNNEL 3.

Close Fit Pipe by Freebore Method

Length. 174m

Diameter. 530

Ground. Shale

Casing Pipe. None

Carrier Pipe. 434 GRP JP

MICROTUNNEL 4.

Close Fit Pipe by Freebore Method

Length. 177m

Diameter. 530

Ground. Shale

Casing Pipe. None

Carrier Pipe. 434 GRP JP

MICROTUNNEL 5.

Close Fit Pipe by Freebore Method

Length. 84m

Diameter. 530

Ground. Shale

Casing Pipe. None

Carrier Pipe. 434 GRP JP

MICROTUNNEL 5.

Close Fit Pipe by Freebore Method

Length. 126m

Diameter. 530

Ground. Shale

Casing Pipe. None

Carrier Pipe. 434 GRP JP