PROJECT OVERVIEW.

20 – 30m microtunneling averaged per day

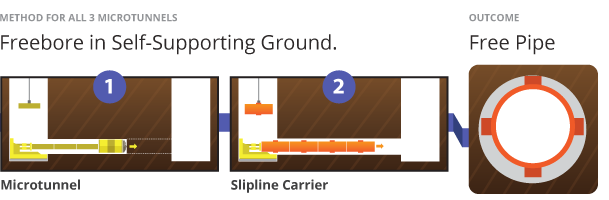

3 microtunnels were 170+ metres (229m, 175m, 176m). The production rate ranged between 20 and 30m per day. Including set up and pipe pushing the project took 9 weeks from mid July to mid September.

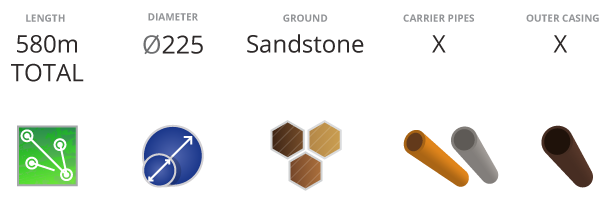

580m microtunneled with no added water.

Killard Excavation won the head contract and excavated the drilling shafts. All 3 microtunnels were completed as single drives from the downstream end of each bore. There was little ground water moisture which allowed most of the 580m to be microtunnelled without any added water.

Drilling rods being lowered into shaft with an excavator

Freeboring in progress

Spoil Heap. Dry ground conditions enabled dry drilling.

2 vacuum tanks, modular vacuum power unit and the hydraulic power unit on site.