PROJECT OVERVIEW.

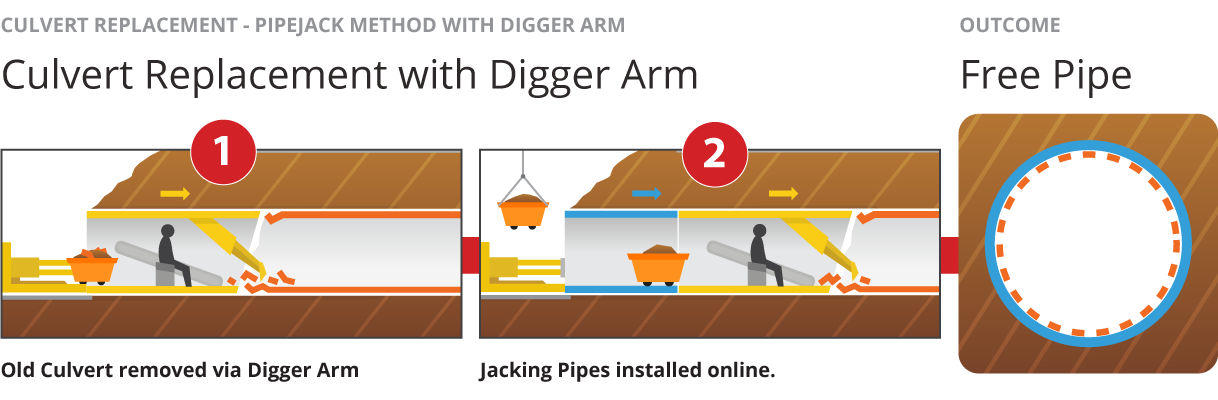

Culvert Replacement

The culvert appeared to have been installed in two sections – the latter when the Hume Highway was widened. A weak point in the centre had collapsed to less than half diameter making it unsuitable for relining or sliplining.

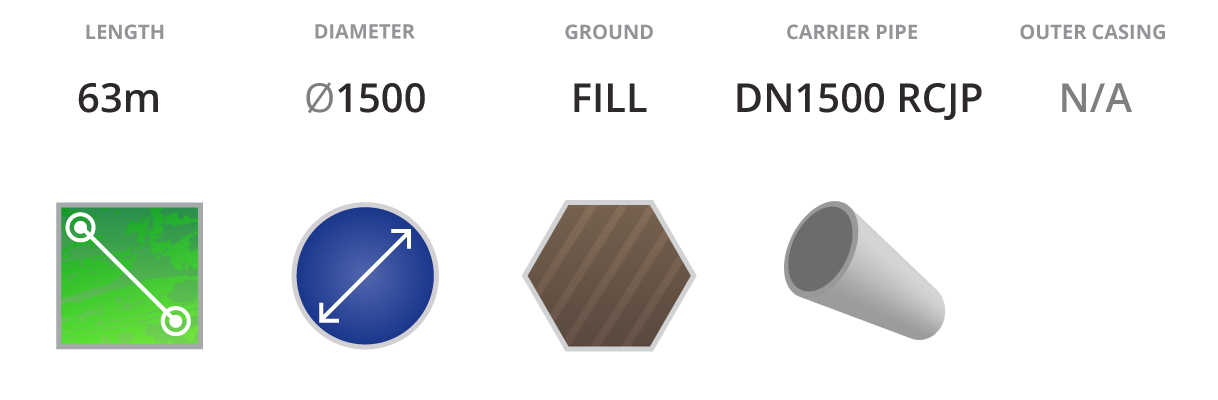

An 1800 diameter jacking shield (sized for a DN1500 Reinforced Concrete Jacking Pipe) was used to surround the failed steel culvert – providing support while the old culvert is removed.

Pipejacked Culvert Installation with continual Ground Support

The new DN1500 RCJPs were pipejacked (installed) immediately behind the shield to provide continual support of the ground while the old culvert was removed.

The end result is a brand new, concrete water tight culvert in place of a failing corrugated steel culvert without open cutting the highway.

Existing Culvert to be replaced, beneath the Hume Highway

Corrugated Steel Culvert to replaced

Inside the existing steel culvert

DN1500 RCJP’s for the new culvert

Pipejacking DN1500 RCJP’s

Launch of Digger Arm Shield

Inside the shield, spoil and old culvert removed

Reaching the weak point of collapse in old culvert

Existing Steel culvert collapsed to nearly half height.

New culvert installed

New culvert installed

Jacking Frame slab left to easily form up head wall

Damaged steel culvert after removal

Walking new culvert