PROJECT OVERVIEW.

244m single drive

One bore in particular was in a deep area. The designers designed manholes approx 250m apart in accessible areas. A microtunnel was required to construct the pipeline between them at a particularly flat grade, so accuracy over that distance was paramount.

The shafts were setup for an intercept bore as, depending upon ground conditions, it may not have been possible to bore the entire 244m from one end. As it turned out, the bore was completed successfully from one end in favourable conditions. There was no need to intercept the first bore from the far end.

Installing the PE250

Diona installed the polyethylene carrier main by stringing it out on the surface and pulling it through. They agreed that this was a difficult task at such depth – with poly being not that flexible at that diameter during the colder months.

A better solution would have been to have Pezzimenti install 3m GRP lengths for the same result.

Two other shorter pipejacks were completed on the same Project under Camden Valley Way and Bringelly rd using steel sleeve as the enveloper. Once completed, the GRP carrier main was inserted and grouted.

Operator and Top Man at the 7.3m deep shaft. The drill rods on the rack ready to be craned below.

View from out of the Container Truck looking down the length of the 244m freebore.

Looking at the site setup in the direction of the 244m single drive

It was planned, if required, that this 244m would be an intercept bore – where one microtunnel targets another from the opposite direction creating one long tunnel – however ground conditions were favourable and the length was completed in a single drive.

Harnessed operator climbing into the 7.3m deep shaft

Control box is craned to the operator below

During microtunnelling the operator monitors the spoil being extracted under vacuum

The 610 Steel Casing Pipe and 450 GRP pipe stockpile

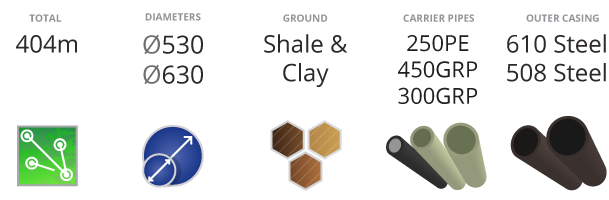

MICROTUNNEL 1.

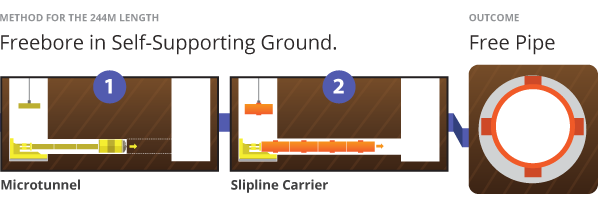

Free Pipe by Freebore Method

Length. 244m

Diameter. 530

Ground. Shale

Casing Pipe. None

Carrier Pipe. 250PE

MICROTUNNEL 2.

Pipe in a Pipe by Pipejack Method

Length. 80m

Diameter. 630

Ground. Clay

Casing Pipe. 610 Steel

Carrier Pipe. 450 GRP

MICROTUNNEL 3.

Pipe in a Pipe by Pipejack Method

Length. 84m

Diameter. 530

Ground. Clay

Casing Pipe. 508 Steel

Carrier Pipe. 300 GRP