PROJECT OVERVIEW.

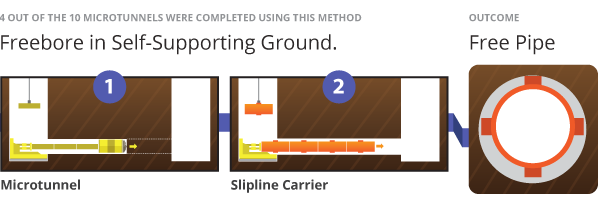

Self-Supporting Ground

The majority of the pipeline was located in shale. This meant that steel sleeve was not required as an enveloper pipe – given the ground self supports – the bore stays true to shape until grouted. The original design had steel sleeve along the entire route – by not using steel sleeve this saved the developer and SWC approx $200/m and also saved time by not having to insert it.

Where the ground didn’t self support or where the bore travelled under an existing dam, sleeve was required.

All of the bore shafts were located in quite difficult to get to areas. Machinery configuration had to be flexible to accommodate some tight situations. The vacuum could stand remote from the shaft using vacuum hose to join in with the jacking frame.

Weather Conditions Overcome

During March and April, access to parts of the golf course were limited due to flooding so the project had to stop for two months. Heavy vehicles simply couldn’t get to the areas required.

Once the weather dried up again, the works were completed with time being caught by up using two crews – one to bore and the other to follow pushing in the pipes and grouting. This saved around 4 days per bore.

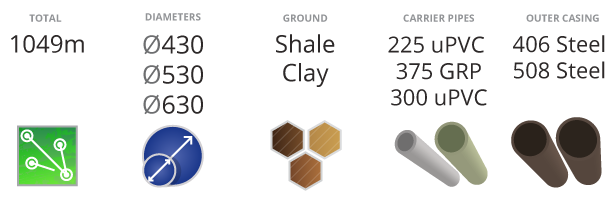

1049m was microtunnelled on this project.

Site Layout next to putting green and fairway

Site Setup

Site Setup

The trailer mounted Hydraulic powerpack and the Vacuum truck were main equipment on site. The top man prepares a drill rod for cranage by excavator

Drill rods ready for loading via the container truck

Top man lowering rods down into shaft using the gantry winch

Loading the 406 Steel Casing

Pipejacking the 406 Steel Casing

The vacuum truck captures and transports spoil

The Hydraulic power pack and vacuum truck setup

300 uPVC stockpile with spacers attached

MICROTUNNEL 1.

Free Pipe by Freebore Method

Length. 86m

Diameter. 630

Ground. Shale

Casing Pipe. N/A

Carrier Pipe. 375GRP

MICROTUNNEL 2.

Free Pipe by Freebore Method

Length. 143m

Diameter. 630

Ground. Shale

Casing Pipe. None

Carrier Pipe. 375GRP

MICROTUNNEL 3.

Free Pipe by Freebore Method

Length. 77m

Diameter. 630

Ground. Shale

Casing Pipe. None

Carrier Pipe. 375GRP

MICROTUNNEL 4.

Pipe in a Pipe by Pipejack Method

Length. 61m

Diameter. 530

Ground. Shale

Casing Pipe. 508 Steel

Carrier Pipe. 300 uPVC

MICROTUNNEL 5.

Pipe in a Pipe by Pipejack Method

Length. 100m

Diameter. 530

Ground. Shale / Clay

Casing Pipe. 508 Steel

Carrier Pipe. 300 uPVC

MICROTUNNEL 6.

Pipe in a Pipe by Pipejack Method

Length. 103m

Diameter. 530

Ground. Shale / Clay

Casing Pipe. 508 Steel

Carrier Pipe. 300uPVC

MICROTUNNEL 7.

Pipe in a Pipe by Freebore Method

Length. 55m

Diameter. 530

Ground. Clay

Casing Pipe. 508 Steel

Carrier Pipe. 300 uPVC

MICROTUNNEL 8.

Free Pipe by Freebore Method

Length. 156m

Diameter. 440

Ground. Shale

Casing Pipe. None

Carrier Pipe. 300 uPVC

MICROTUNNEL 9.

Pipe in a Pipe by Pipejack Method

Length. 117m

Diameter. 430

Ground. Clay

Casing Pipe. 406 Steel

Carrier Pipe. 225 uPVC

MICROTUNNEL 10.

Pipe in a Pipe by Pipejack Method

Length. 90m

Diameter. 430

Ground. Clay

Casing Pipe. 406 Steel

Carrier Pipe. 225 uPVC

MICROTUNNEL 11.

Pipe in a Pipe by Pipejack Method

Length. 61m

Diameter. 430

Ground. Clay

Casing Pipe. 406 Steel

Carrier Pipe. 225 uPVC