PROJECT OVERVIEW.

Microtunnelling in tight spaces

Both the sewer and stormwater systems were located approximately 100m on the other side of a retirement village. En route was a boundary fence, gardens and backyards within the village.

Geotechnical investigations were undertaken indicating rock along the route. This enabled Pezzimenti to freebore, pull out then slipline the pipes. This was most beneficial as there was not enough room to build a full shaft at the upstream end to remove the head.

Solid vs Fill Ground

However, when the bore shaft was excavated, fill was found. This type of fill could not be bored through. Thus one section was open cut along the fence causing a disruption to the houses and fence line to a point mostly solid ground was found. The bore began here. With the stormwater being so close to the surface, this was necessary to avoid a cave in on the 950mm bore. One advantage of the container truck was that it could fit up a 4.5m easement to reach where this point was. The vacuum was located some 50m away in a car park. Spoil was taken off site in bins.

The sewer, being deeper, was founded in solid ground and was a successful free bore.

The Gantry of the container truck extends over the shaft for cranage of the equipment and drill rods. Vacuum hoses can be seen running to the Vacuum bins which capture the spoil.

Shaft in tight spaces

The site setup in the tight spaces. The Hook truck with a water bin loaded, a water bin, powerpack and the container truck.

Inspecting some of the debri being pulled back via the vacuum.

Top men lowering drill rods to the jacking frame via the container truck crane. Tight proximity to residential properties.

Operator Paul launches the microtunnelling head

Container and water bin proximity

Water Bin

The 900mm GRPJP stockpile

MICROTUNNEL 1.

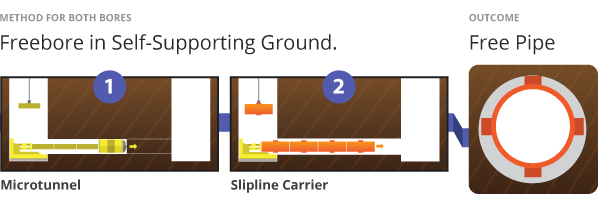

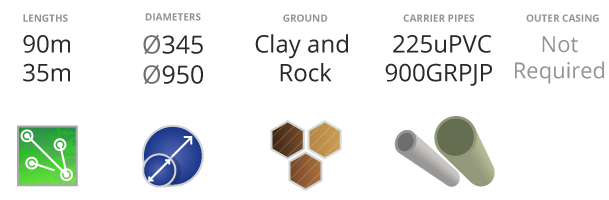

Free Pipe by Freebore Method

Length. 90m

Diameter. 345

Ground. Clay

Casing Pipe. None

Carrier Pipe. 225uPVC

MICROTUNNEL 2.

Free Pipe by Freebore Method

Length. 35m

Diameter. 950

Ground. Rock

Casing Pipe. None

Carrier Pipe. 900GRPJP